Pictures and video of the final product (2nd prototype):

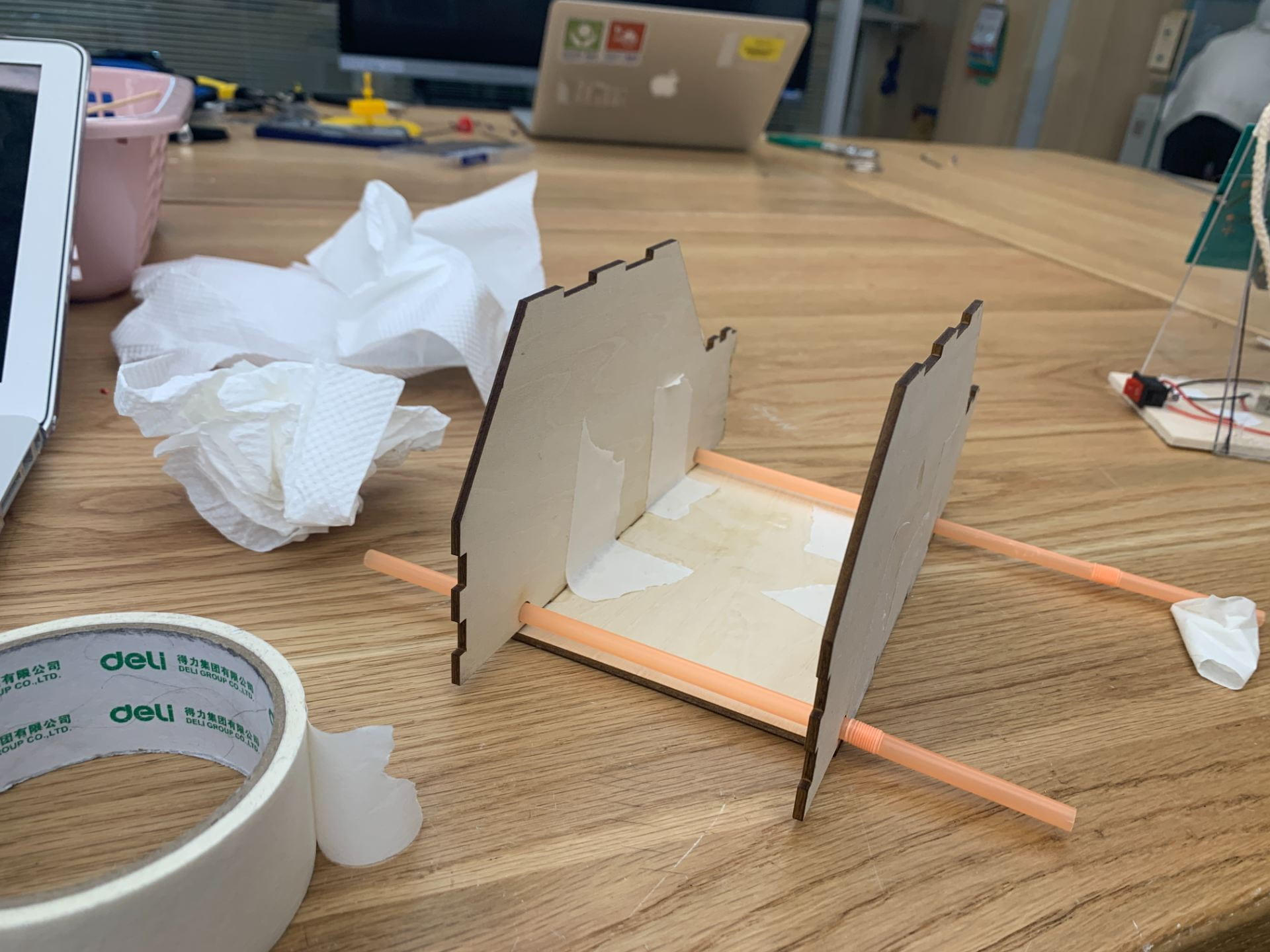

(1st prototype:)

IMG_3062 (Link to a video showing the winding and releasing of the 1st prototype)

I intended on my product to rely on elastic energy to propel the car forwards, thereby resulting in kinetic energy. When the vehicle is pulled backward, the spinning of the back axle results in the winding of the rubber band around the back axle, which results in tension applied on the rubber band and the rubber band extending longer, which prepares and expands the elastic potential energy stored in the rubber band. When the car is released, the tension from the rubber band is released and the rubber band contracts, where the back axle spins with assistance and as a result of the contracting action of the back axle. The back axle is connected to wheels which, when turned, will result in the car being propelled forwards (kinetic energy). Although some energy is lost in the form of thermal energy (due to friction) and sound energy (from the “snapping” of the contracting rubber band, the intended output (kinetic energy) is achieved before the car slows down due to friction. Thus, the toy begins with elastic (potential) energy, then leads to mechanical energy (spinning of the axle), and consequently ends with kinetic energy (movement of the car).

It is of my opinion that I was largely successful in producing a functional test prototype that primarily works as intended, allowing me to test the product and analyze improvements that I can make. I was also quite successful in the development and plan stage of the design project because I believe that I have made a good plan that details the product that I will make, albeit with a few discrepancies and mistakes.

I think I can improve on my time management since I could have used my time more wisely and had finished my project as a result. I also believe that I could work on the aesthetics and design elements of the product. Although my product looks decent with neat laser-cut edges wood, I could possibly add windows, doors, or other etched decorations onto the body to improve the looks of the product.

The product is primarily intended for children to learn about energy change and at the same time have a toy that they can play around with, resulting in the children (which is the target audience/client) having fun and learning at the same time. The adjustable position of the rubber band (in the 1st prototype) can also allow for the client to explore how initially tensioning or relaxing the rubber band will affect the movement of the car, allowing for analysis of this toy as part of an experiment. I also envisioned so that objects could be placed on top of the car (on the roof), allowing for more experimentation and seeing how added mass will affect the distance traveled or other factors.

The impact my product has on the environment is not too positive, since I relied on laser-cut wood to make my product. Some areas that could be sustainable or more friendly to the environment include the straws to hold the axles, which can be made from used straws to support sustainability, and the skewers acting as axles, which can be made from used or reused skewers.