MY TAKEAWAYS AND REFLECTION

what impact did your initial problem analysis have on your planning?

To begin with, acknowledging my time and resource constraints allowed me to formulate a timeline that would keep my work organized. Knowing the time limit offered influenced me to distribute an equal amount of work to be done in each class, allowing me to complete the project on time, with quality.

Prior considerations of manufacturing problems also helped me carefully think through the materials and procedures I would take in order to enhance the quality of the product. For example, I took into account of the materials I would use. Therefore, I had them ready prior to my practical manufacturing classes to ensure that everything flows out smoothly. I have also watched through tutorials at first to be certain that I am equipped with all the skills needed to build the device.

What am I proud of?

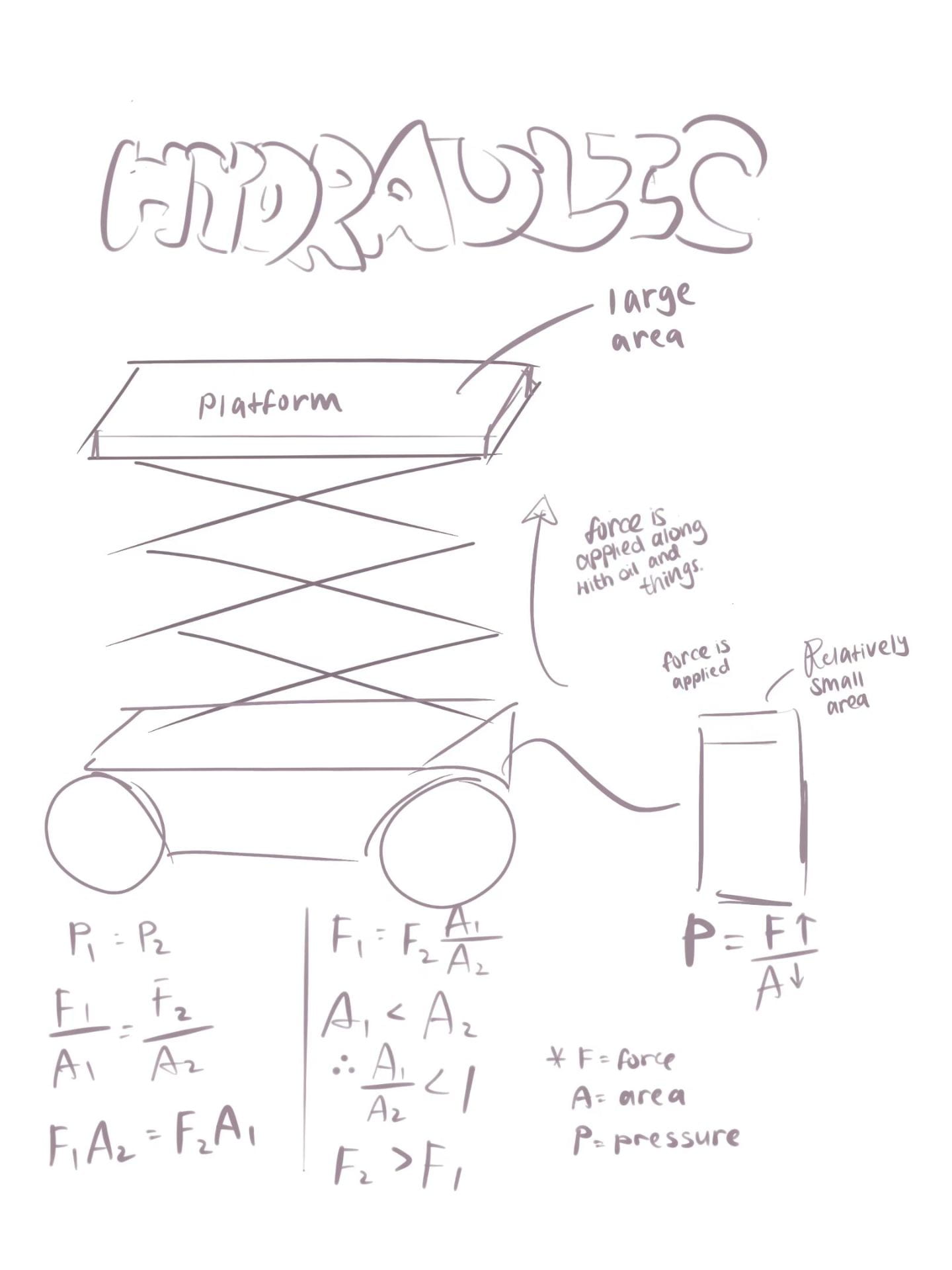

This project is completely self-based, and is the first individual engineering project we’ve had. I’m grateful that I have completed the project by conducting my own research, making the device, and performing trials. I’m also glad that I have reached my success criterias, showing the energy transfer of hydraulic energy to mechanical energy. The lift is able to operate like expected, and I have completed the project on time.

What could I have done differently if I was given more time?

There were many flaws in my final project, including mis-drilled holes and areas I missed out on gluing. These steps weren’t major issues, but refining them would improve the overall quality of the scissor lift. For example, as shown in my final video, one of the corner wasn’t even tangible. This was because I overestimated and did not carefully plan out where to drill the holes. I drilled by using my vague perception, causing a lot of the sticks to be unequal, creating an imbalance in the final product. This imbalance of sticks made the lift slightly slanted, which affected the objects it could carry. If I had put more effort into contemplating about small details like this, it would improve both the appearance and practical use of my device.

Would have my alternative choices worked better?

I genuinely believe my choice of creating a hydraulic lift was a success, and my alternatives wouldn’t have been a replacement for this project. I had lots of fun throughout the creation process, and learning about hydraulic force was also interesting. The wind turbine and the lamp would have both required more knowledge associated with electrical circuits, which would be difficult to learn. I believe the alternative ideas would utilize more time, and especially since I was absent for a class, the hydraulic lift was an appropriate project to complete over the course of the two weeks.

Overall, I believe my ‘Hydraulic Lift’ had achieved the goal of this unit; I attained the goal I have set prior to this project, which is for the device to satisfy the needs of energy capture & storage. I especially enjoyed the process and had lots of fun. It enhanced my knowledge on energy transfer and also allowed me to practice more on-hand skills that prepares me for future projects.

Real life example:

Real life example: